The Stir magazine, Volume 7 no. 5, (issue Oct./Nov.18) with our SC130N advertising is online now:

Please also see the Interview with our managing director, Farhad Pirouz,

Responsible Packaging:

Farhad Pirouz grew up with the tea industry. As owner, managing director, and c.e.o. of DPH Group in Cologne, Germany, he has established a reputation within the packing industry for meeting every packaging need in tea.

DPH is a one-stop company with manufacturing capability for advanced automatic tea bag packing machines and, as a supplier of expendables including filter paper, aluminum wire, cotton thread, printed tags and protective envelopes. Farhad joined DPH in 1991 and is responsible for several product divisions including tea. Under his direction, the firm offers start-up feasibility studies, factory layout, and technical support as well as financing.

Before joining DPH he held managerial positions at Daimler Benz and Continental AG. Tea is mainly old in outdoor markets, roadside stands, and at the farm gate without the benefits of packaging. Pirouz travels frequently to origin where he advocates on behalf of tea communities seeking to maximize efficient and sustainable returns by adding value.

STiR: Will you share your thoughts on why packaging tea is so important to the sustainability of the tea industry?

Pirouz: There are two main aspects in terms of sustainability in my view.

One is the sustainability of our tea itself, leading others to meet the following challenges: a) keep the taste of tea consistent to enable individual preference in preparation; b) ensure the natural health and wellness characteristics of teas; c) maintain a consistently high level of quality; d) keep the volume of tea used to make each cup consistent; and e) maintain the ease of preparation in a reasonable time.

Second is to ensure the availability of tea every day in our marketplace, such as where we, as consumers demand to find and buy our tea. We must make sure that supply meets demand in the years ahead when tea production is predicted to decrease.

The answer to both concerns is a single solution: responsible packaging. Not only does packaging provide an extremely accurate level of consistency in terms of taste, quality, color, and volume of tea needed and therefore minimizing waste, packaging also addresses health issues with proper dosing in the preparation of a cup of tea. These are all important characteristics for the consumer. Packaging forces brands to control their suppliers in meeting accepted standards. Controlling volume simultaneously regulates consumption of tea for the perfect cup while reducing waste worldwide.

Packaging allows you to control all factors to ensure the sustainability of the tea itself and its availability as a commodity. A critical question facing us in the future is how to meet growing global demand by the year 2050 when it is predicted the industry will face a significant decrease in global tea production. In my view, packaging will play an extremely important and critical role in meeting this shortfall.

DPH Group is working in close partnership with the dominant manufacturers of machines and materials, to provide both the equipment and services to satisfy the need to industrialize our market by building up the value-added segments of the supply chain within our tea and coffee industry.

STiR: Only about 12% of the world’s tea volume is packaged in tea bags. China, for example, consumes far more tea than Russia, but most is consumed as freshly made loose leaf. Using Russia as an example, will you explain how the availability of packed tea is transforming that market. In 2017 about 56% of the total tea consumed in Russia was in teabags, for which it must allocate hard currency in US dollars, which limits other economical budgeted expenditures.

Pirouz: China, for the past 13 years, has been the world’s largest producer and is once again the largest tea exporter. China’s domestic market consumed 2 million metric tons of tea last year, averaging 1.5 kilos per person per year. In China, unlike Russia, the majority is consumed in a loose tea format. Less than 0.8% of tea production is packed in teabags ― about 10,000 metric tons, mostly in double-chamber, single-chamber, and pyramid shaped tea bags. If China were to control tea consumptions by packaging it in tea bags a huge amount of tea would be saved. This tea would be available for export, generating foreign currency as an export commodity and creating even more income. Packaging adds value and increases tonnage available for export.

Contrast that to Russia which imports much of its tea packed in teabags. That allows Russia to bring in millions fewer tons of tea and to save on consumption per cup of tea. Instead of dosing loose tea at 3 grams per cup, teabags brew the same volume using 1.5 to 2 grams of tea.

A large number of HST and Teepack machines from Germany are used in Russia to achieve this high level of value addition. Others from Italy, like ACMA and IMA, also contribute. In the single-chamber packaging market, DPH recently launched the new “SMART LINE” machine which packs up to 130 teabags per minute and includes different top options to the machine without raising the competitive price.

Countries like India, Kenya, Vietnam, Indonesia, and others should make a much greater effort to adopt policies that target a greater scale of value addition, enabling them to conserve quantities and/or earn more on their relevant commodity tea. Our Smart Line machines make it economically easy to get into the value addition in these countries.

STiR: Tea packing is experiencing significant innovation in polymer reinforcement, shape, and characteristics of filter papers such as composability and recyclability. Will you address the innovations you find most promising and explain why?

Pirouz: We are in partnership with Glatfelter’s composite fibers business unit, the industry’s main supplier of quality non-heat-sealable and heat-sealable filter paper out of Germany, France, and the UK. Glatfelter focuses on providing our clients with a range of options that gives them choices as to how they serve the market. We have developed papers which have less reliance on abaca by using alternative cellulosic fibers that maintain both excellent conversation and endurance performance characteristics. When it comes to heat sealable filter papers Glatfelter has led the way in using currently available bioplastics to replace standard oil-based aliphatic hydrocarbons such as polypropylene. Glatfelter assures me that by way of this substitution Glatfelter has now developed a range of papers which contain fibers that are biodegradable and industrially compostable and can run on all major machine platforms such as HST, Teepack, IMA, ACMA, Maisa, DPH’s Smart Line, and others. So, while offering excellent particle retention, superior infusion, and conversion characteristics, Glatfelter provides a more environmentally friendly product profile.

We at DPH are also working closely with Rychiger AG from Switzerland, the leading manufacturer of capsule filling and sealing machines. They also are working toward environmentally friendly materials for the capsule use that we all hope will be successful and serve our market.

STiR: Packing is the greatest source of value addition in the tea industry. Describe how adding value near origin can benefit growers facing increasing costs of production.

Pirouz: Teabags require about half the amount of loose leaf tea used to make a cup. This is an indication of the huge potential impact of what could be saved if we make full use of controlled consumption.

This is critical because a growing population, rising middle class, and greater urbanization in developing countries is going to increase demand. At the same time a combination of climate change, water shortages, an overall decrease in the amount of agricultural land, and increasing competition between food crops is going to reduce supply.

Value addition begins with the process of the tea preparation as it is dried, cleaned, cut, blended, and packed. A market which has successfully implemented the value addition will create jobs, increase wages, generate taxes, encourage spending, and increase the nation’s gross national product. The whole macro-economic chain is set into force to the good of these countries’ economic framework.

Each link adds value. Machines are being engineered and produced, wages are being paid, and last, but not least, the packing itself enables us to ask for higher prices per packed volumes. At present, except Sri Lanka, Japan, and South Korea, most of the tea growing countries are a long way from incorporating teabag packing into their markets. They still export big volumes unpacked.

Countries importing these teas in bulk in Europe or the US have installed the value chain into their markets and have the most benefit of earnings through adding the value chain. In the UK 96% of tea is consumed in teabags; in Germany, it’s 92%; and in the US it’s 65%.

As production costs rise and competing crop management in the countries of origin reduces the amount of land available to grow tea, the question arises: Why not establish a value chain in the country of our tea’s origin so that suppliers in-country can begin with planting and end by packing tea in teabag formats?

The opportunity to create significant earnings is obvious. Our company and team would be ready to consult and lead with support to everyone who asks for. We have concepts, the different machines of different choice, the materials, and offer technical and financial services.

STiR: Describe how value addition can capture foreign exchange revenue to expand exports and offset social costs that better the lives of workers.

Pirouz: Packing tea within the country of origin, as you see in Sri Lanka, for example, boosts the entire country’s GNP. You can generate much greater income than you spend buying machines and materials and building the necessary infrastructure. This was demonstrated by Teepack after they invented the teabag packing machine in the early years and thereafter sold a big number of machines worldwide. For the economy, it is much cheaper to invest in machines, materials, and services and build up the value chain and earn the relevant income in hard currencies such as US dollars and euros. This can be done at a much greater scale at the point of origin compared to spending year by year an enormous foreign exchange amount to import tea to satisfy the demand in the market.

The value chain in the country of origin improves social costs that benefit the whole circle - labor, wages, taxes, spending, and a growth of the GNP - while controlling volumes needed to make our cup of tea.

Tea importing countries save hard currencies they would otherwise have to spend for their imports; those countries who grow tea reduce the volume for local consumption so there is more tea available for export, earning additional income.

Dan Bolton is managing editor of STiR coffee and tea.

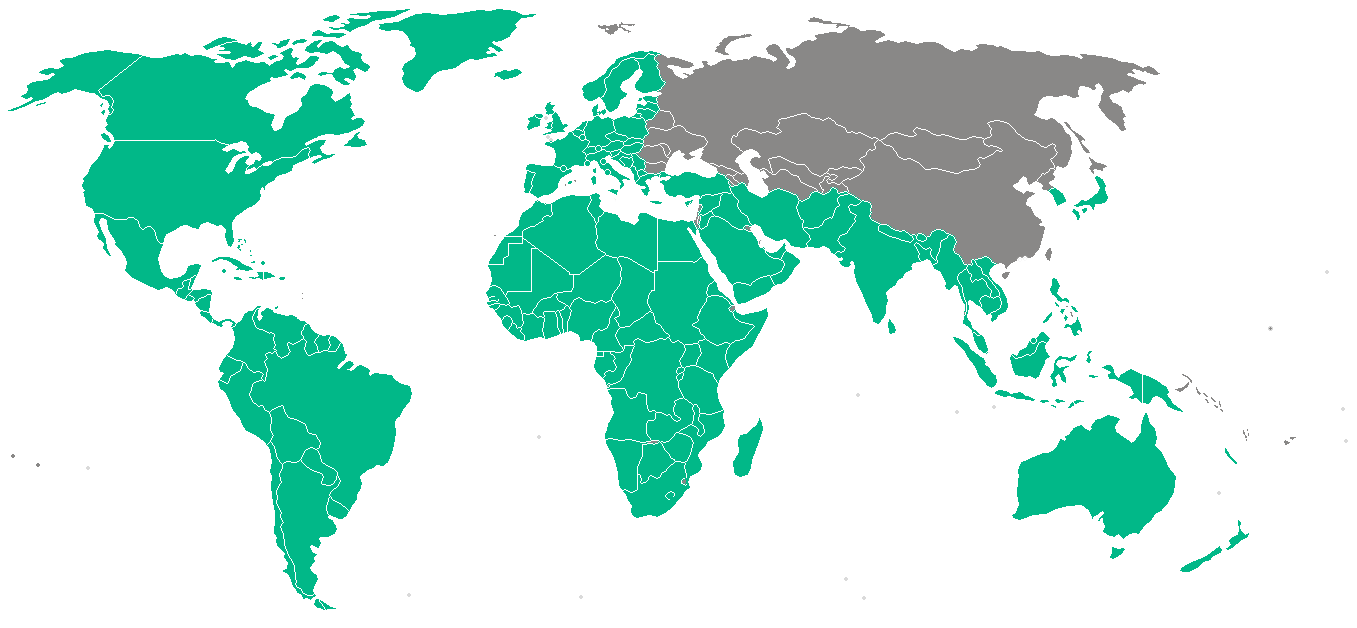

dph - worldwide operations

-

dph is looking for agents in:

Indonesia, Bangladesh, Pakistan, South-East-Asia

Myths & Variants as to the origin of tea

Did you know that the tea bag was invented inadvertently?

In 1908 The New York tea importer Thomas Sullivan was sending tasting tea samples to his customers. Because he could not ship loose tea, and the shipping was too expensive in heavy tin cans, he packed the samples in small mousseline bags. However, the customers did not unwrappe the tea and dipped the whole bag into the water. They found the invention of the tea bag pretty handy - even though if it was not foreseen by Sullivan.

Tea has played a significant role in Asian culture for centuries:

According to one legend Bodhidharma founder of the Zen school of Buddhism, after meditating for nine years, he accidentally fell asleep. He woke up in such disgust at his weakness, he cut off his eyelids and they fell to the ground and took root, growing into tea bushes.

In one popular Chinese legend around 2737 BC, Shennung, the legendary Emperor of China, inventor of Chinese medicine, was drinking a bowl of boiling water. The wind blew and a few leaves from a nearby tree fell into his water and began to change its color. The ever inquisitive and curious monarch took a sip of the brew and was pleasantly surprised by its flavor and its restorative properties.

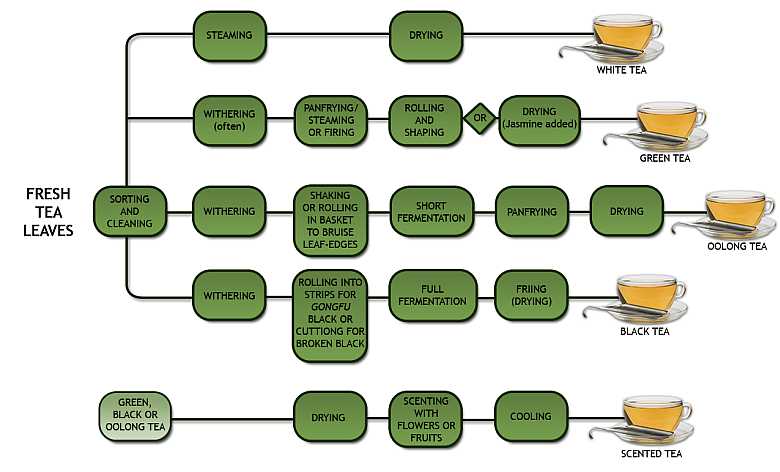

Tea Processing

All teas come from the same plant. The differences stem from how they are processed.

Freshly harvested leaves contain 75-83% moisture while processed tea has a moisture content of less than 3%. Tea production is simply a drying process. However some chemical changes take place by natural fermentation which gives different varieties of teas.

Black Tea undergoes a full fermentation process composed of four basic steps - Withering, Rolling, Fermenting, and Firing (or Drying).

There are two types of Black tea processing

-

Orthodox this is the traditional method or the hand method.

-

CTC (Crush, Tear, Curl)

Green tea

Green tea is often referred to as "unfermented" tea. The freshly picked leaves are allowed to dry, then are heat-treated to stop any fermentation (also referred to as oxidation.)

Oolong tea

Oolong tea is generally referred to as "semi-fermented" tea for the manufacture of oolongs; the leaves are wilted in direct sunlight, and then shaken in bamboo baskets to lightly bruise the edges. Next, the leaves are spread out to dry until the surface of the leaf turns slightly yellow. Oolongs are always whole leaf teas, never broken by rolling. The least fermented of oolong teas, almost green in appearance, is called Pouching.

White tea

White tea it is the least processed of its many varieties. The new tea buds are plucked before they open and simply allowed to dry. White tea is not oxidized or rolled, but simply withered and dried by steaming.

Flavored tea

Flavored tea is created when the additional flavorings are mixed with the leaf as a final stage before the tea is packed. For Jasmine tea, whole jasmine blossoms are added to green or oolong tea. Fruit-flavored teas are generally made by combining a fruit's essential oils with black tea.

Tea Picking

The best tea leaves are small and young, and plucked from the tip of the tea bush (this is known as "Orthodox" method).

Categories of leaf size used as deciding factors for picking.

Flower Pekoe Tiny shoots and unopened buds are picked.

Orange Pekoe Youngest opened leaves are picked.

Souchong Older, coarser leaves closer to the trunk of the shrub are picked

Another factor in the picking of young leaves is calling a "flush" This is when there is a sprouting of new buds and leaves on a plant. These fresh young leaves and buds are then picked. A tea plant may flush more than three times within a single growing season.

Tea Weighing

On receipt of tea at the factory from the estate, the fresh tea leaves are weighed and recorded.

Sorting & Cleaning

The dry tea leaves received are sorted & cleaned

Withering:

Tea leaves are spread on racks or troughs to reduce their moisture content.

Rolling & Breaking:

Tea leaves are rolled in order to break down their structure and release their natural juices and enzymes. This begins the fermentation process.

Fermentation:

Takes place when tea is spread on trays in a cool, humid atmosphere to oxidize the leaves. It changes the chemical structure of the leaf, the leaves turn from green to coppery red. The longer a tea is allowed to ferment, the stronger flavor it will have and the darker it will become. Some teas are not fermented at all.

Firing & Baking:

The leaves are dried and the fermentation process is retarded. In this stage, the leaves move through hot air chambers to stabilize the leaves and lock in the flavor.

Farhad Pirouz, managing director and C.E.O. of dph tea bag machine company in Germany, explains that “the greatest value addition in tea is the packaging segment.” During a presentation at the 5th Global Dubai Tea Forum last April Pirouz said that tea bags account for 12% of the volume of world production but “their sales value is much higher”.

Farhad Pirouz, managing director and C.E.O. of dph tea bag machine company in Germany, explains that “the greatest value addition in tea is the packaging segment.” During a presentation at the 5th Global Dubai Tea Forum last April Pirouz said that tea bags account for 12% of the volume of world production but “their sales value is much higher”.