Special features of FS 120

- Small footprint

- Plug & Produce concept

- Single-lane tool arrangement -> excellent accessibility

- Individually controlled, servo-driven dosing augers with optional

feedback loop for weight control - MAP enclosed smart flow section for all processes from filling to

sealing - Individually controlled and heated punching and sealing tools with

one-stroke technology - Secondary packaging unit for cartons (optional

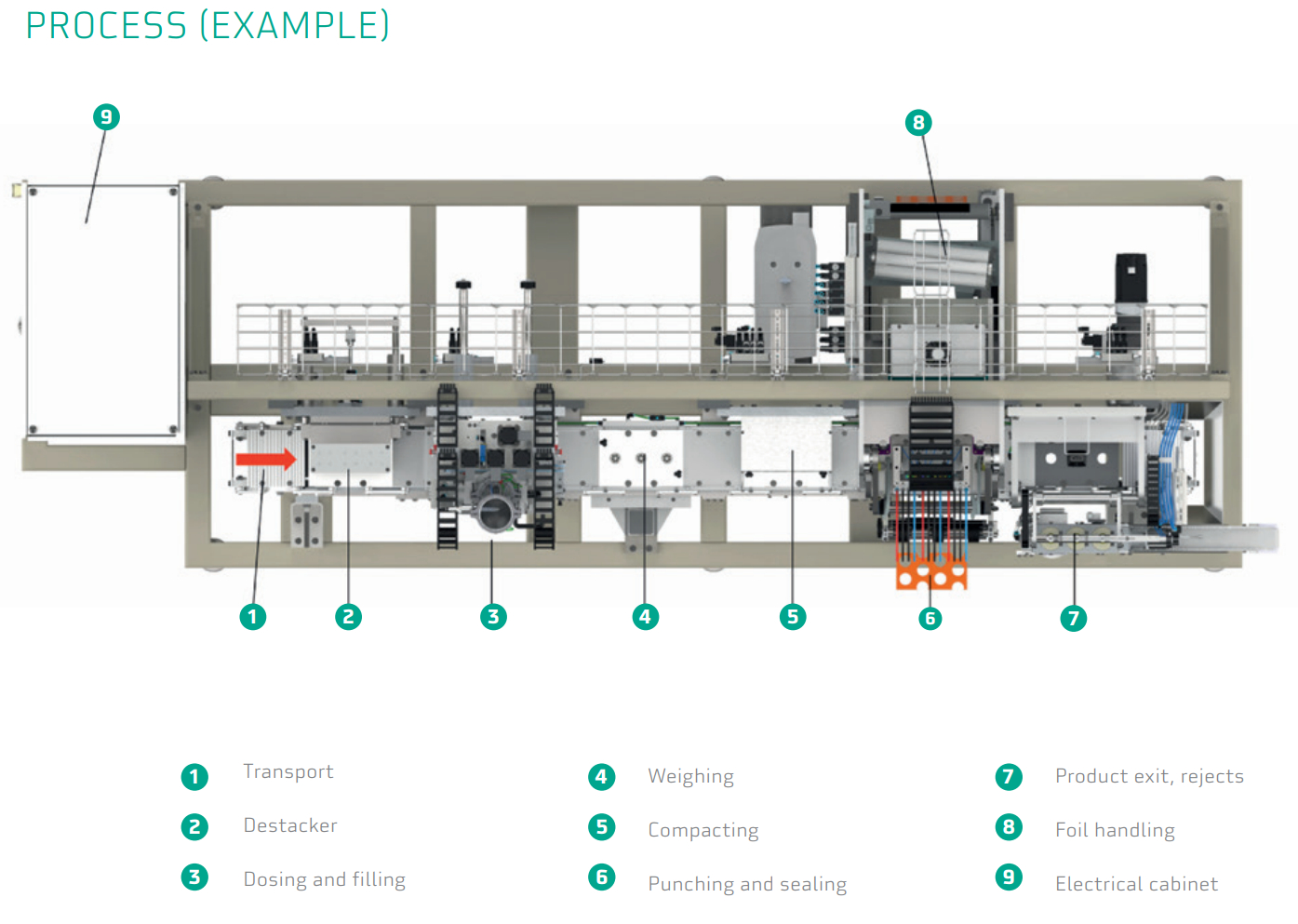

Linear transport system

- High-precision, servo-controlled linear capsule transport

- Linear arrangement of processing tools providing easy access

- Quick and easy changeovers

- Easily expandable for additional modules (option at the time of order)

Capsule infeed

- Destacker for stackable capsules

- Capsule magazine designed for easy refill

- Capsule sorting, orienting and feeding system for non-stackable, capsules supplied in bulk (optional)

Dosing and filling

- Volumetric, dosing by means of individually controlled dosing augers

- Control of individual servo-driven dosing augers by means of

downstream weighing cells - Weight control of all completed capsules on downstream load cells

- Custom-engineered auger geometry for all different applications

- Dosing of liquid flavouring agents (optional)

MAP

- Filling and sealing under protective gas in MAP tunnel

Punching and sealing

- Punching and sealing of lidding and filtering material with one-

stroke technology - Punching and sealing for roll stock material, or sealing with pre-

punched lids - Individually controlled punching and sealing tools

- Heat sealing or ultrasonic sealing (Option)

- Rugged, high-precision module with closed force flow loop

Operation and control

- Touch screen with intuitive user interface

- Plain text error messages (optional)

Optional equipment

- Bulk feeding systems

- High-precision weight measurement with feedback loop to dosing

augers - Camera systems for visual inspection

- MAP tunnel

- Secondary packaging unit

- Flavouring Module